Tuesday, March 31, 2015

Our Advanced Spring Design 7.0.13 software includes programs

for compression springs in series as well as in parallel. This allows for spring designs which change

in stiffness as the loads increase.

Variable pitch springs have an initial stiffness until those

coils with the smallest pitch begin to go solid. Here’s an example along with a plot of the

load/deflection curve.

Nested springs of different lengths can also be used to change

the stiffness as the load increases. The

longest spring will resist the load by itself until it deflects to the length

of the next longest spring and then both will be engaged.

Here is an example of three nested springs along with a plot

of the load/deflection curve.

If you haven’t seen this software in action, download a free

trial from our web site http://www.uts.com/Freetrial.asp and/or

call us to schedule a free orientation via GotoMeeting.

Wednesday, July 31, 2013

TK

Model Building with Galaxy in Mind

Galaxy allows application developers to

create custom interfaces for TK Solver models.

Here are some important issues to consider when creating/modifying TK

models to be used in Galaxy applications.

These tips also apply for those who are linking TK models with Excel or

Visual Basic interfaces.

Save

the model with inputs and outputs.

If a model is saved without first being

solved, some of the variables may not get output values and Galaxy may not be

sure as to how to categorize them. It’s

always a good idea to set up a model with typical inputs and solve before

saving.

Save

the model with consistent units displayed.

Make a pass through the variable sheet and

make sure that all the variables have consistent display units. For example, users may not notice that one

variable is shown in meters while the rest are in millimeters.

Do

not use any interactive TK functions.

QUERY, PROMPT, MENU, DEBUG, PAUSEMSG, SHOWMATRIX,

and BOXMSG all create interactive pop-ups when the model executes. These will not function within Galaxy. Galaxy includes controls that allow you to

build your own prompts and menus.

Be sure to check start-up procedure functions

as well as they often include such functions.

ERRMSG is ok to use but check to make sure that the error wouldn’t be

better trapped in the interface instead of during the solution process. For example, Galaxy allows you to set limits

on input values.

Avoid

plot legends and static annotations.

These do not move predictably as the

solution changes. Programmable

annotations are preferred as they can be placed at specific plot locations

using procedure functions and the locations will automatically change as values

change in the model.

Models

should be set up to solve without manual guessing wherever possible.

A model should solve automatically for most

practical combinations of inputs. The

model should include iteration triggers which are not default first guesses for

the variables appearing in Galaxy. You

do not want default guesses appearing automatically when insufficient inputs

are supplied by the users who have no way of knowing if the value which appears

is a unique solution.

Use

Procedure Functions to Generate Lists of Solutions

List solving should be avoided when

possible and replaced by procedure functions which loop through lists of input

values. When list solving is required,

use start-up functions to automatically generate the input list(s) based on

inputs on the variable sheet.

Merge

Included Objects

Galaxy will not have access to the included

objects in your TK files. You must merge

them into a single file before importing that file into Galaxy.Thursday, May 16, 2013

Case Study: Rapid Conversion of a Technical Paper to a Mathematical Model

A technical paper, in PDF form, containing an algorithm with over sixty linear, nonlinear and integral equations is converted to a mathematical model in TK Solver and subsequently linked to Excel and a web application. The math model was completed in one day and the links and refinements to the interface were completed on day two.

The Model Building Process

The technical paper was ESDU Data Item 85007, entitled “Contact Phenomena III: Calculation of Individual Stress Components in Concentrated Elastic Contacts Under Combined Normal and Tangential Loading.” It was made available in PDF form.

The PDF file was briefly reviewed and it

was noted that two complete examples were provided within the document, either

of which could be used to verify a computerized version of the formulas and

calculations.

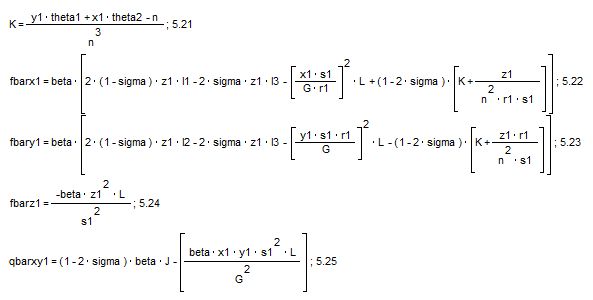

The formulas were entered into TK

Solver. Here is a sample of some of the

formulas, in TK’s MathLook View including the equation numbers from the paper:

The variables in the equations are

automatically summarized on TK’s variable sheet, including descriptions and

units. Here is a portion of the variable

sheet, with the inputs grouped at the top.

The model also includes many auxiliary

variables used by the ESDU algorithm. Those variables are grouped together on the

variable sheet. During the testing of

the model, it was very useful to be able to verify that each intermediate value

was computed as specified by the paper.

Here is a portion of that listing.

The calculations required three numerical

integrations. Fortunately, TK Solver

includes built-in functions for those calculations. Here are the integrands.

The limits of the integrals were determined from the solution of a sixth order polynomial. It was necessary to find all the roots and then use the largest real root in the upper limit of integration. TK Solver includes a root finder that was perfect for the task, based on Bairstow’s algorithm for finding real and complex roots of nth-order polynomials. A loop was added to select the best one for this application. TK’s unique capability to mix rule-based equation solving with calls to procedural subroutines was a time-saver.

Here is the procedure that sets up the polynomial, solves it with a call to the Bairstow function and then picks the best solution for the application.

Interfacing with Excel

The TK file was linked to an Excel spreadsheet, as shown below. There are several advantages to this. The underlying formulas can be hidden. The interface can be customized. The TK model can be used as a function within a larger spreadsheet application. The spreadsheet and model can be packaged together and shared with anyone.

The TK file was linked to an Excel spreadsheet, as shown below. There are several advantages to this. The underlying formulas can be hidden. The interface can be customized. The TK model can be used as a function within a larger spreadsheet application. The spreadsheet and model can be packaged together and shared with anyone.

The spreadsheet dynamically updates as the

inputs are changed. The plots were added

by taking advantage of TK’s powerful “List Solve” feature to repeatedly solve

the equations over a range of inputs for one of the variables.

Interfacing with the Web

The TK Solver model was also processed using a UTS tool called Galaxy, which automatically builds a browser interface for a web-based application. Again, the variables displayed in the browser interface are dynamically linked to the model.

The TK Solver model was also processed using a UTS tool called Galaxy, which automatically builds a browser interface for a web-based application. Again, the variables displayed in the browser interface are dynamically linked to the model.

Odds and Ends

There are a number of additional features of TK Solver that make it an excellent tool for such applications.

There are a number of additional features of TK Solver that make it an excellent tool for such applications.

Units management is one TK’s strengths. In

this application, unit conversions are available for all the inputs and

outputs. You can globally swap between

US and SI units or mix and match as you like.

This feature carries through to the Excel and Web interfaces as well.

Table and plot generation is another asset. Any

mathematical model built in TK Solver can be enhanced without any additional

programming required. As shown, the

effects of varying the friction angle are plotted and automatically updated as

other variables change. Even the

locations of the plot annotations dynamically change.

Backsolving

is perhaps TK Solver’s most valuable feature.

Backsolving allows users to input a desired value for one or more

outputs and solve for the required inputs.

One example for this model would be to input a stress value and have TK

determine the required friction angle or contact dimension. Here is one such example. Note that fy, the component stress with the

maximum absolute value, has been input and the contact length, a, has been solved.

In this way, a single TK Solver model

actually solves much more than the initial intent of the technical paper, with

no additional programming required.

In summary, a technical paper containing

dozens of pages of equations is now accompanied by a mathematical model that

the reader can immediately use to solve any related problems. With much more functionality than FORTRAN or

BASIC translations of the formulas could provide, the TK Solver model gives the

reader a dynamic way of turning a complex document into a handful of variables

that are easily understand and manipulated.

Best of all, the entire process only required a couple days.

Tuesday, March 26, 2013

TK Solver for Chemical Engineers

Overview

TK Solver is frequently used for

calculations involving mass balances, fluid flow, distillation,

agitation/mixing, combustion, heat transfer, dust/mist collection, and reactor

design. The program includes built-in

thermodynamic and transport property functions based on the NIST Standard

Reference Database 23. Additional material

property tables and curves can be integrated into TK models. TK’s unique backsolving capability allows

engineers to optimize designs according to their process/performance

requirements. The versatile TK library

of mathematical and statistical tools handles critical number crunching tasks

such as nonlinear curve-fitting, simulation, and solutions of differential

equations.

Chemical engineering educators also find TK

useful because of its structured approach to model building and its powerful

equation solving and unit conversion abilities.

Students can progressively build on previously learned concepts. TK’s List Solve feature empowers students to

explore the sensitivity of the variables in their models, generating tables and

plots of important relationships -- even those involving large sets of

nonlinear equations. Engineering

textbooks are available which integrate TK into the teaching of chemical

engineering.

Glimpses

of the History of TK Solver in Chemical Engineering

Since its initial release in 1983, TK

Solver has proven to be a very powerful and practical tool for chemical

engineers. It has also been favorably

reviewed many times from a variety of perspectives. Here are some examples:

Mark Jennings, Digital Kinetics -- Mr.

Jennings used TK Solver to develop and publish PCOST, an extensive collection

of process and pollution control equipment costing models based on a series of

articles published in Chemical Engineering magazine.

Vijay Singh, Schering-Plough, for Chemical

Engineering Magazine -- Mr. Singh presented material balance and flash

calculation examples, concluding that “TK reduces the time spent on problems by

allowing the engineer to concentrate on defining the solution rather than

working out the mechanics of the computer program required. It allows for the formulation of design

models in a natural equation form... It

greatly facilitates the exploration of “what-if” situations.”

D.W. Pepper and A.H. Weber, DuPont, for the

Journal of the Air Pollution Control Association -- Pepper and Weber discussed

calculations involving accidental atmospheric dispersions and reported that TK

Solver is easy to program and, because it can backsolve problems, can yield

quick, reasonable estimate of the source term.

Allan L. Smith, Drexel University

Department of Chemistry -- “Every student said that TK Solver was easier to use

than the programming languages they knew.”

Professor Smith has used TK Solver to model the composition of “acid

rain”.

Gerald Rich for Pollution Engineering

Magazine -- Mr. Rich reviewed TK Solver and summarized, “This is a simple,

fun-to-use program for solving equations.”

Edward M. Rosen, Monsanto Co. -- Mr. Rosen

investigated TK Solver’s equation solving capabilities as applied to four

chemical engineering problems:

fractional conversion in a chemical reactor; energy and material

balances; plug flow reactor equilibrium conversion and temperature;

kinetics. Successfully solving all four

problems with TK Solver, he concuded that TK is a useful tool for chemical

engineers.

Curt Arnold, M.W. Kellogg, quoted in

Digital News -- “Although we have promoted TK inside the company primarily for

relatively simple calculations, we have some very large models with 800 to

1,000 rules. These systems handle

complicated problems such as modeling steam systems for process plants, very

difficult and very important calculations.”

Ali Cinar, Illinois Institute of Technology

-- Volume II of the HAWK MANUAL, published by IIT to assist engineering

students in learning to use computers, features 22 engineering case studies and

corresponding TK Solver models. Mr. Cinar’s

case study models an ammonia reactor operation and the effects of inerts

molefraction level on recycle streams.

Amoco Production Company and the American

Petroleum Institute teamed up with UTS to develop TK Solver applications for

the API Gas Measurement Manual.

Z.Z. Zhang, Donald L. Sparks, and Noel

Scrivner; Characterization and Modeling

of the Al-Oxide/Aqueous Solution Interface, published in the Journal of

Colloid and Interface Science -- The authors, from DuPont and the University of

Delaware, successfully used TK Solver to build their mathematical model and

study the sensitivity of the variables involved.

Dan Deitz, Mechanical Engineering

Magazine -- To determine the

specifications for a combustor in a high-speed civil transport plane, Pratt

& Whitney engineers are using TK Solver to solve hundreds of complex

equations. The article focuses on TK’s

many unique features put to use in solving heat transfer problems.

UTS released Heat and Mass Transfer on TK,

a collection of TK Solver models co-authored with Professor David DeWitt of

Purdue University.

UTS and BHR Group Ltd. produced an on-line

electronic information system called Intermix, based on the FMP and HILINE

Design Guides for fluid mixing. The

following topics are covered -- motionless mixers as liquid-phase and

gas-liquid reactors, ejectors as gas-liquid reactors, rotor stator mixers as

liquid phase reactors, and centrifugal pumps as liquid phase reactors.

A Case Study:

DuPont’s Chemical Process Design Standards are an excellent example of web-based smart standards. DuPont engineers have accumulated four volumes of chemical process design standards. There are well over one thousand pages of formulas, figures, and descriptions. DuPont worked with Universal Technical Systems, Inc. to produce the web-based version of these standards.

Many topics are covered:

· fluid flow through pipes and orifices

· heat transfer

· agitation and mixing

· distillation

· dust and mist collection

· physical properties of materials

Many of the paper standards required the users to refer to figures for use in intermediate calculations. Many of these figures required users to visually interpolate within families of curves. The TK Solver software was used to process the data within these curves numerically, interpolating automatically where necessary.

Unit conversions were also handled using TK Solver. The equations were all entered using the established nomenclature for each variable. Conversion factors are automatically applied if the user wishes to view a variable in a different unit.

Perhaps the most important use of TK Solver is for backsolving problems. Once the equations are set up in TK, they can be solved in any direction depending on which variables are known and unknown. For example, a standard which computes the pressure drop from turbulent flow through a pipe can also be used to size a pipe for an allowable pressure drop. A single standard easily solves many combinations of problems.

Another major enhancement to the standards was to incorporate a database of physical properties into the calculations. DuPont has a license for the DIPPR physical properties database. That information is now used during the calculations from the standards. Users specify the substances they are working with and properties such as viscosity, density, and vapor pressure are applied at various temperatures. The integration with TK Solver means that these material property calculations can also backsolved. The result is that users can backsolve for temperatures at which to operate various processes for desired performance. Users gain a better understanding of the relationships between variables.

A Summary of TK’s Competitive Advantages for Chemical Engineers

TK Solver has many great features but the following ones really make TK stand out as the preferred tool.

• TK is easy to program. -- TK’s rule-based approach to model building allows engineers to enter equations just as they know them, without the need for algebra. Other programs require assignment statements where an unknown must be isolated.

• TK can backsolve. -- TK can solve problems for many combinations of inputs and outputs without any additional programming or rearranging of variables or equations. Backsolving facilitates better designs.

• TK can list solve. -- TK can solve problems repeatedly over a range of inputs to generate data for tables and plots. This feature works for models involving simultaneous nonlinear equations as easily as for simpler problems. This feature can easily be used for filtering random numbers through math models for Monte Carlo simulations.

• TK can optimize -- TK can solve problems repeatedly within given constraints to determine the optimal configuration of inputs.

• TK does table look-ups. -- TK can access material property tables and charts during model resolution and can interpolate within them as well. TK also backsolves table look-ups to find necessary inputs producing the desired properties.

• TK is uniquely programmable. -- TK combines both rule-based and procedural languages for the best of both worlds. Users can implement their own algorithms and use the resulting functions within TK as they would any of the built-in functions. Even backsolve them! It’s easy to save these functions and merge them into other models as necessary.

• The TK Library. -- Engineers with math and statistical requirements such as solving differential equations, fitting curves to experimental data, or even a combination of these two, will find a treasury of pre-programmed tools in the TK Library, all at no extra cost.

TK Solver Library Highlights:

List/array manipulation

Matrix manipulation

Root finders

Numerical differentiation

Numerical integration

Differential equation integrators

Optimization algorithms

Geometry and CAD functions

Functions of complex variables

Data analysis and statistical testing

Linear and nonlinear curve-fitting

Curve-fitting of differential equations

Probability distributions

Maximum likelihood estimation

Monte Carlo simulation analysis

Wednesday, December 09, 2009

FOR IMMEDIATE RELEASE

December 9, 2009

Advanced Spring Design 7 Release is “Unbelievable”

New Features and Spring Types Make ASD7 an Essential Upgrade.

A joint project between Universal Technical Systems, Inc. (UTS) and the Spring Manufacturers Institute (SMI) since its first launch in 2003, Advanced Spring Design Release 6 has always lived up to its name, advancing spring design to the next level, saving spring designers time and reducing the margin for human error. After a number of intermediate updates, a totally new ASD 7 is now released making the newest product a must have for every spring designer. ASD7 meets all of your spring design needs in a single program, combining engineering expertise with customized calculations created in TK Solver’s collaborative environment to help you design quality springs.

Dick Carter, an Engineering Manager from Michigan Spring & Stamping has been using ASD6 since its beta version in 2003 and has done several thousand designs. He notes “with the upgrade to ASD7, spring design becomes increasingly robust over a larger variety of spring types.”

Some of the new spring types included in ASD7 are:

Dick Carter isn’t the only user impressed by ASD7, Tom Lusinski, a Plant Manager, Spring Division, and Spring Estimator for Stanley Spring & Stamping has been using ASD6 for the past few years for all of his spring design needs on a day-to-day basis. Describing ASD6 as “fantastic,” Lusinski was blown away by ASD7. “It is unbelievable… the new features and help module offered in ASD7 are state-of-the-art.”

New Features in ASD7 Include:

ASD7 contains a flexible database of materials with a new estimation routine for minimum tensile strength, making it easier to add your own materials. Other time-saving features include the ability to combine cylindrical and conical compression springs in a series (stacked or continuous) and in parallel (nested). Because it runs on TK Solver, ASD7 lets you “backsolve” your designs, allowing you to solve your problem in any direction, and gives you a means of designing a spring with variable pitch, rate, size, and other characteristics.

“I never thought that spring design software could do any more than ASD6 was doing, but I was terribly wrong,” says Lusinski. Other ASD7 users are bound to agree.

Since 1933, the Spring Manufacturers Institute (SMI) has served North American manufacturers of springs and their associate suppliers.

Universal Technical Systems, Inc. has been a leading provider of high-productivity problem-solving software products and custom developed solutions, including the highly-regarded TK Solver, since 1984. Visit http://www.uts.us.com/ or call 815-963-2220 to schedule your free trial and demonstration of ASD 7.

Contact: Todd Piefer, Todd.piefer@uts.us.com (815) 963-2220

###

Additonal Information:

ASD7 Product Page

Brochure and Fact Sheet

December 9, 2009

Advanced Spring Design 7 Release is “Unbelievable”

New Features and Spring Types Make ASD7 an Essential Upgrade.

A joint project between Universal Technical Systems, Inc. (UTS) and the Spring Manufacturers Institute (SMI) since its first launch in 2003, Advanced Spring Design Release 6 has always lived up to its name, advancing spring design to the next level, saving spring designers time and reducing the margin for human error. After a number of intermediate updates, a totally new ASD 7 is now released making the newest product a must have for every spring designer. ASD7 meets all of your spring design needs in a single program, combining engineering expertise with customized calculations created in TK Solver’s collaborative environment to help you design quality springs.

Dick Carter, an Engineering Manager from Michigan Spring & Stamping has been using ASD6 since its beta version in 2003 and has done several thousand designs. He notes “with the upgrade to ASD7, spring design becomes increasingly robust over a larger variety of spring types.”

Some of the new spring types included in ASD7 are:

- Systems of compression springs in series and in parallel

- Internal and external garter springs

- Constant force spiral springs

- Stacked Belleville washers

- Internal and External snap rings

Dick Carter isn’t the only user impressed by ASD7, Tom Lusinski, a Plant Manager, Spring Division, and Spring Estimator for Stanley Spring & Stamping has been using ASD6 for the past few years for all of his spring design needs on a day-to-day basis. Describing ASD6 as “fantastic,” Lusinski was blown away by ASD7. “It is unbelievable… the new features and help module offered in ASD7 are state-of-the-art.”

New Features in ASD7 Include:

- Non-linear rates for conical compression springs

- Ability to calculate torsion at arm and arm length calculations

- Variable pitch and diameter on single springs

- Context-sensitive help linked to the SMI Encyclopedia

- Built-in curve-fitting routine for tensile strength data

- Life plots with default or user-defined S-N curves

- Improved management of saved designs

- 3D images produced for each design

- Notes can be saved with each design

- “Enterprise” option for sharing designs across networks

ASD7 contains a flexible database of materials with a new estimation routine for minimum tensile strength, making it easier to add your own materials. Other time-saving features include the ability to combine cylindrical and conical compression springs in a series (stacked or continuous) and in parallel (nested). Because it runs on TK Solver, ASD7 lets you “backsolve” your designs, allowing you to solve your problem in any direction, and gives you a means of designing a spring with variable pitch, rate, size, and other characteristics.

“I never thought that spring design software could do any more than ASD6 was doing, but I was terribly wrong,” says Lusinski. Other ASD7 users are bound to agree.

Since 1933, the Spring Manufacturers Institute (SMI) has served North American manufacturers of springs and their associate suppliers.

Universal Technical Systems, Inc. has been a leading provider of high-productivity problem-solving software products and custom developed solutions, including the highly-regarded TK Solver, since 1984. Visit http://www.uts.us.com/ or call 815-963-2220 to schedule your free trial and demonstration of ASD 7.

Contact: Todd Piefer, Todd.piefer@uts.us.com (815) 963-2220

###

Additonal Information:

ASD7 Product Page

Brochure and Fact Sheet

Wednesday, December 02, 2009

Tutorial Video: Differential Equations #5

Built upon Differential Equations #4 includes showing the use of the new ODE Wizard which automates some of the steps required.Differential Equations #5

Tutorial Video: Differential Equations #4

Built upon Differential Equations #3Differential Equations #4

Tutorial Video: Differential Equations #3

Built upon Differential Equations #2Differntial Equations #3

Tutorial Video: Differential Equations #2

Built upon Differential Equations #1Differential Equations #2

Tuesday, December 01, 2009

Tutorial Video: Differential Equations #1

We’re going to record some video tutorials for a variety of TK Solver topics. The tutorials will be posted in the support section of the UTS web site. Each one will be about five minutes in length and in some cases we’ll include a series of several videos to cover topic. These will be based on text from existing documentation and case studies written over the years but it’s often much more efficient to have a video to see it in action. The sessions will not necessarily go into every bit of detail but should be useful for people who want to follow along, pausing to try the same things on their own computer if necessary. We are interested in getting suggestions for video topics. A sample can be seen in the link below.Differential Equations #1

Labels: Tutorial Video